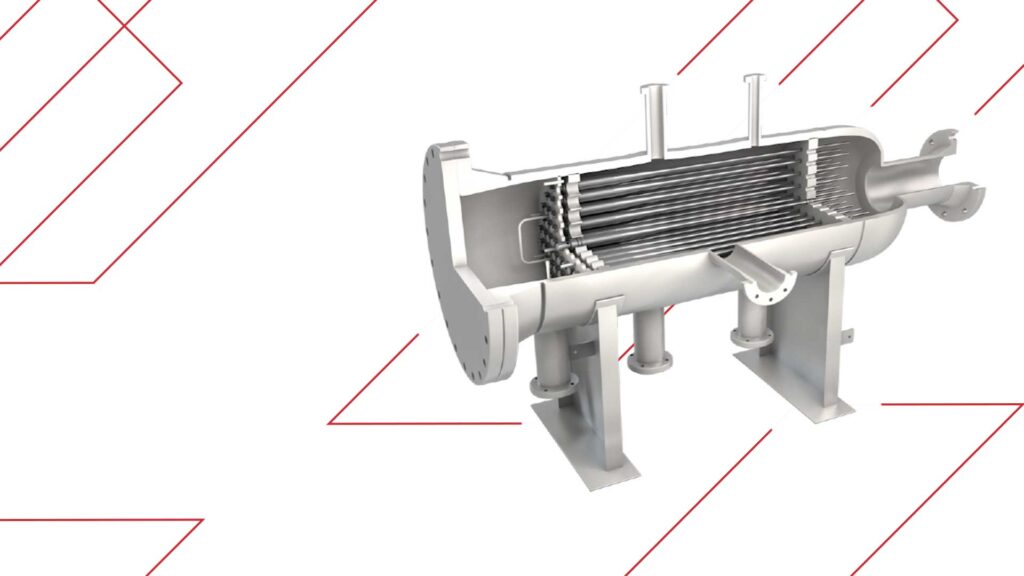

Separon™ Deoilers effectively remove oil from water using centrifugal-action. The Deoiler hydrocyclones, liners represent the state of the art in primary Produced Water Treatment technology. Unlike conventional hydrocyclones, we supply advanced, technology-based products that offer solutions to the oil & gas industry from the wellhead and downhole.

Separon™ DEOILER, key features:

- Stable oil core provides higher separation performance.

- No moving parts; saves maintenance time and cost.

- Low and steady pressure loss saves energy and provides predictable flow rates and operating system.

- Designed to handle slugging, upset situation and high solids loading provides predictable operating system.

- Enhanced inlet ports for optimum oil recovery.

- Choice of profiles to accommodate space and piping limitation making for an easy layout and installation.

- Systems and skidded units available.

- Light weight and small footprint.

- Not affected by fluctuations in motion (suitable for FPSOs).

- Annular axial inlets reduce turbulence.

- Multiple inlets improve wear resistance.

- Involute can be inspected without liner disassembly.